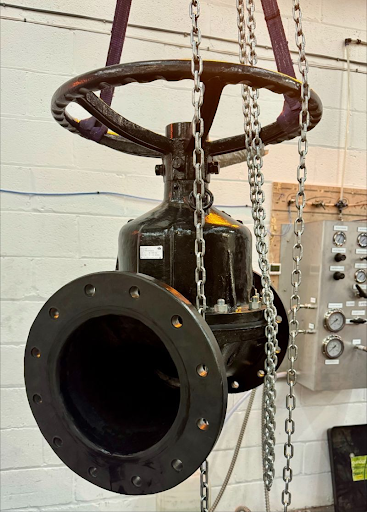

DN250 Rubber Lined ST Diaphragm Valve Aces Hydro Test, Bound for Finland

KDV Flow UK, a global leader in industrial valve manufacturing, has recently completed hydro testing a DN250 Non-Rising Rubber Lined Straight Through Pattern Diaphragm Valve. This valve, built for demanding industrial environments, is now en route to Finland, where it will be distributed by Starline Valves Oy, a leading valve supplier in the region.

Key Features:

- DN250 Size: Ideal for handling substantial flow rates.

- Non-Rising Stem Design: Ensures compact installation and minimizes operational footprint.

- Straight Through Pattern: Maximizes flow efficiency and reduces pressure drop.

- Rubber Lining: Provides unparalleled resistance to corrosive media and abrasive slurries, ensuring extended service life.

- Rigorous Testing: Each KDV valve undergoes stringent quality control measures, including a hydro test, to guarantee optimal performance and reliability.

Destination: Finland

This DN250 diaphragm valve is destined for the Finnish market, where it will be distributed by Starline Valves Oy, a leading supplier of valve solutions in the region. Finnish industries will benefit from the exceptional performance, durability, and reliability that KDV valves are known for.

Which type of diaphragm valve is best suited for products containing solids or viscose fluids?

The combination of the straight through pattern, rubber lining, and tight shut-off capabilities makes this KDV diaphragm valve the optimal choice for handling viscous fluids. It ensures smooth flow, prevents corrosion and wear, and minimizes the risk of leaks.

Who Should Consider this Valve?

Industries that regularly handle viscous fluids, such as chemical processing, water treatment, and mining, would benefit significantly from this KDV diaphragm valve. Its durability, reliability, and specialized design make it a valuable asset in these sectors.

Why Choose KDV Rubber Lined Straight Through Diaphragm Valves?

- Straight Through Pattern: This design minimizes turbulence and pressure drop, making it ideal for viscous fluids.

- Rubber Lining: This provides exceptional resistance to corrosive and abrasive substances often found in viscous fluids, ensuring a longer lifespan for the valve.

- Tight Shut-Off: This feature prevents leaks, which is essential for maintaining process integrity and preventing product loss, particularly with viscous fluids.

- Low Maintenance: The straightforward design and easily accessible components reduce downtime for inspection and maintenance, a crucial factor in industrial settings.

About KDV and Starline Valves Oy:

KDV is a global leader in the design and manufacture of high-quality industrial valves, renowned for their exceptional performance and longevity. Starline Valves Oy, our trusted partner in Finland, shares our commitment to providing top-notch valve solutions to meet the unique needs of the Finnish market.

For more information on KDV’s extensive range of diaphragm valves, please visit our website or contact your local distributor. Finnish customers can reach out to Starline Valves Oy for inquiries and orders.

- Uncompromising Quality: We use only the finest materials and employ stringent quality control measures.

- Innovative Design: Our valves are engineered for optimal performance and efficiency.

- Global Expertise: With a worldwide presence, we understand the unique needs of diverse industries and applications.

Customer-Focused Service: We prioritize building strong relationships with our customers, offering support and solutions tailored to their specific requirements.

Keep an eye on our website and social media channels for the latest updates on our DN25 BSPP valve production, the exciting news from KDV Flow Benelux, and other developments that showcase our commitment to innovation and customer satisfaction.