Things You Must Know About Diaphragm Valve And How It Works

Diaphragm valves are the most reliable solution for the corrosive and abrasive flow of media. The characteristics of this valve work well to provide an efficient and cost-effective application. The earliest diaphragm valves were made by the Greeks and Romans. It traces back to their origins to ancient Greek and Roman civilizations, where they played a role in managing water systems, particularly for public baths and aqueducts. These early valves were ingeniously simple yet effective for their time. To control the flow of water, the diaphragm was manually pressed against a raised weir, a structural feature that interrupted the flow path and created a seal. This mechanism allowed for the regulation of both the flow and temperature of water, critical for maintaining the functionality of the famed Roman hot baths, or thermae.

KDV Valves and the innovation in these early valves lay in their ability to create a leak-tight seal, a principle still central to modern diaphragm valves. Their understanding of water pressure and flow dynamics is evident in the extensive aqueduct systems, which relied on various valve designs, including precursors to diaphragm valves, to distribute water efficiently across cities.

With all the amazing benefits it can do, Check out how diaphragm valves work and see if they are the perfect choice for your needs.

Diaphragm valves use a flexible diaphragm connected to a compressor by a stud which is molded into the diaphragm.

Diaphragm valves operate using a flexible diaphragm as their core component, which serves as both the sealing element and the mechanism for controlling fluid flow. The diaphragm is typically made from durable materials like rubber, elastomers, or synthetic polymers, selected based on their compatibility with the fluids and operating conditions. This diaphragm is securely connected to a compressor (or actuator plate) through a stud that is molded into the diaphragm. This design ensures a reliable and efficient connection between the moving parts.

When the valve is operated, the compressor moves the diaphragm, pressing it tightly against the weir or seat within the valve body to form a leak-proof seal and stop the flow of fluid. When the compressor retracts, the diaphragm lifts away from the seat, allowing fluid to flow freely. This motion is controlled with precision, making diaphragm valves ideal for applications requiring exact flow regulation.

Instead of pinching the liner closed to provide shut-off, the diaphragm is pushed into contact with the bottom of the valve body to provide shut-off.

Unlike other valve types that rely on pinching a liner or compressing a material to achieve shut-off, diaphragm valves utilize a unique design where the diaphragm is pushed downward into contact with a raised weir or the bottom of the valve body. This action creates a positive seal, effectively isolating the flow of fluid. The diaphragm conforms tightly to the seating surface, ensuring a leak-proof shut-off even under high-pressure or vacuum conditions.

This design eliminates the need for additional seals or gaskets that could wear out over time, making diaphragm valves particularly reliable and low-maintenance. Moreover, because the diaphragm is the only moving component in contact with the fluid, it protects the rest of the valve’s internal components from exposure to corrosive, abrasive, or sensitive materials. This feature is especially valuable in applications where maintaining the purity of the fluid or preventing contamination is critical, such as in food and pharmaceutical processing.

This creates an airtight seal that opens and closes when pressurized air is applied. The media flows through small holes in the diaphragm which allows it to be actuated quickly and accurately. Diaphragms can also be used on throttling applications where flow needs to be controlled more precisely. When selecting a diaphragm valve, choosing the appropriate diaphragm material is crucial to ensure optimal performance, longevity, and reliability in your application. Diaphragms are available in several materials, including rubber, PTFE (polytetrafluoroethylene), and metal, each offering unique advantages and limitations that must be carefully evaluated based on the specific operating conditions.

- Rubber Diaphragms

Rubber diaphragms are widely used in general-purpose applications due to their cost-effectiveness and good abrasion resistance. They perform well in low to moderate temperature environments and can handle fluids containing particulates. However, rubber is vulnerable to degradation when exposed to aggressive chemicals, oils, or solvents, and is generally unsuitable for systems involving steam or high-temperature media, as excessive heat can compromise its integrity.

- PTFE Diaphragms

PTFE diaphragms are ideal for applications involving corrosive chemicals or high temperatures, as they offer excellent resistance to a wide range of chemical agents and can withstand exposure to steam. Their smooth, non-stick surface also minimizes the risk of contamination, making them a preferred choice in pharmaceutical, food and beverage, and chemical processing industries. However, PTFE is more expensive than rubber and is less resistant to abrasion, which may limit its use in systems with abrasive media.

- Metal Diaphragms

Metal diaphragms are the most durable option, capable of withstanding extreme temperatures, harsh chemicals, and high-pressure conditions. They are often used in industrial applications requiring maximum strength and reliability, such as in petrochemical or high-pressure steam systems. Despite their robustness, metal diaphragms are typically the most expensive and are susceptible to wear when exposed to abrasive particles, which can lead to premature failure in such environments.

Diaphragm Valve Types and How it Works

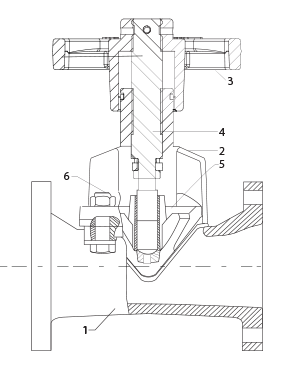

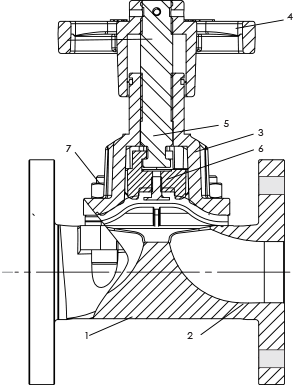

There are two main categories of diaphragm valves: one type seals over a weir and the other (sometimes called a “full bore or straight-through” valve) seals over a seat. In general, straight-through diaphragm valves are used in on-off applications and weir-type diaphragm valves are used for control or throttling applications.

KDV Unlined S traight-through Type Diaphragm Valves (Full Bore):

traight-through Type Diaphragm Valves (Full Bore):

These valves have a straight flow channel that allows fluid to pass with minimal resistance, reducing pressure drops and ensuring efficient operation. The diaphragm acts as a seal, and when compressed by the actuator, it shuts off the flow completely.

This simple design makes them ideal for on/off applications, such as:

- Isolating equipment during maintenance.

- Opening or closing pipelines to control system sections.

- Redirecting flow to different parts of a system.

Advantages: Offers full-flow capacity with minimal pressure drop, making them ideal for on/off applications, viscous fluids, and systems where smooth flow is critical.

KDV Weir-type Diaphragm Valves:

KDV Weir-type Diaphragm Valves:

These valves feature a raised ‘weir’ within the valve body. When the diaphragm is lowered by the actuator, it rests against this weir, creating a controlled restriction depending on the position. This unique design allows for precise flow control, making these valves ideal for throttling applications.

Weir-type diaphragm valves are particularly effective in processes where accurate modulation of flow rates is critical. They excel in tasks such as:

- Pressure Regulation: Maintaining consistent pressure within the system.

- Flow Control in Mixing Processes: Adjusting the flow to ensure proper blending of fluids.

- Chemical Dosing: Delivering precise quantities of chemicals for treatment or production purposes.

Advantages: Superior flow modulation, suitable for slurries and abrasive fluids due to reduced contact area with the seat.

Basic Operation

- Closed State: When the valve is closed, the actuator pushes the compressor down, compressing the diaphragm against the valve seat (either a weir or the valve body base) and creating a tight seal.

- Open State: To open the valve, the actuator retracts, lifting the compressor and allowing the diaphragm to relax and move away from the seat, creating a flow passage.

- Throttling (Weir Valves): Weir-type valves can partially compress the diaphragm against the weir, proportionally restricting the flow for control and modulation.

Material selection for diaphragm valves is crucial for successful operation. Consider the specific characteristics of the fluid that will be handled, including corrosiveness, presence of abrasives, and temperature. If the fluid is acidic, alkaline, or otherwise chemically reactive, choose a diaphragm and body material compatible with that substance. For fluids containing sand, grit, or other abrasive particles, a durable diaphragm material and a wear-resistant valve body lining are essential. Additionally, ensure that the chosen materials can withstand the operating temperatures of your system. Due to their material versatility and isolating design, diaphragm valves excel in industries where fluid handling is critical, such as chemical processing, water treatment, food and beverage, and pharmaceuticals.

FAQs About Diaphragm Valves

1.What are the main differences between diaphragm valves and ball valves?

The key difference lies in their design and functionality:

- Diaphragm Valves use a flexible diaphragm that presses against a weir or valve body to control or stop flow. They are ideal for handling corrosive, abrasive, or sensitive fluids and offer excellent leak-proof performance.

- Ball Valves feature a rotating ball with a hole through the center that aligns with the flow path when open. They are better suited for high-pressure systems and on/off control but are less effective for precise throttling or handling abrasive media. Diaphragm valves also isolate the fluid from the operating mechanism, making them more hygienic and suited for sterile environments.

2. What are the main differences between diaphragm valves and butterfly valves?

Diaphragm and butterfly valves differ in their design, application, and flow control:

- Diaphragm Valves use a diaphragm to create a seal or control flow and are ideal for precise flow modulation and applications requiring leak-proof performance. They excel in corrosive, abrasive, or sterile environments.

- Butterfly Valves have a rotating disc that pivots within the flow path to regulate or stop flow. They are better for high-flow applications, offer a compact design, and are typically used in large-diameter systems. However, they may not provide the same level of precision or isolation as diaphragm valves, especially in handling aggressive media.

3.What are the main types of diaphragm valves, and how do they differ?Diaphragm valves are categorized into two types:

- Weir-Type Valves: Feature a raised weir that the diaphragm presses against for precise flow control, ideal for throttling and modulation.

- Straight-Through Valves: Have a flat flow path, reducing pressure drops and making them suitable for on/off applications with minimal resistance.

4.What materials are used for diaphragm valves, and how do they affect performance?

Diaphragms can be made from rubber, PTFE, or metal:

- Rubber: Cost-effective, abrasion-resistant, suitable for general use, but not ideal for high temperatures or aggressive chemicals.

- PTFE: Excellent chemical and temperature resistance, preferred in corrosive environments, but less durable under abrasive conditions.

- Metal: Highly durable and suitable for extreme temperatures and pressures but costly and prone to wear in abrasive systems.

5.In which industries are diaphragm valves commonly used, and why? Diaphragm valves are used in industries such as:

- Chemical Processing: To handle corrosive fluids.

- Pharmaceuticals: For hygienic, sterile applications.

- Food and Beverage: To ensure contamination-free fluid handling.

- Water Treatment: To control slurries and abrasive materials.

- Mining: For durability in handling abrasive slurries.

If you need diaphragm valves in the UK that stand to be reliable and cost-effective solutions for your next project be sure to check us out. KDV Flow Limited UK is known for its fast turnaround time and lead times when it comes to order fulfillment. It’s made possible by having large stocks of lined valves (different types and Ranges) at our warehouse in Leeds.