PTFE Sleeved Plug Valves: A Growing Demand in the UK

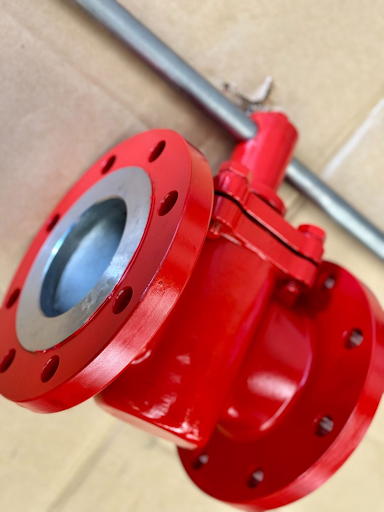

The demand for PTFE sleeved plug valves has been steadily rising within the UK’s industrial valve landscape. This trend is evident in KDV’s thriving collaboration with a UK-based reseller specialising in Alloy 20 PTFE sleeved plug valves. The growing preference for these valves underscores their expanding significance across various UK industries, where their durability and adaptability are increasingly valued.

The demand for PTFE sleeved plug valves has been steadily rising within the UK’s industrial valve landscape. This trend is evident in KDV’s thriving collaboration with a UK-based reseller specialising in Alloy 20 PTFE sleeved plug valves. The growing preference for these valves underscores their expanding significance across various UK industries, where their durability, chemical resistance, and operational flexibility are increasingly valued.

Key Benefits of PTFE Sleeved Plug Valves

Exceptional Corrosion Resistance – The PTFE sleeve acts as a protective barrier, preventing chemical attacks and ensuring long-lasting durability in aggressive process environments.

Bubble-Tight Sealing – These valves offer zero-leakage performance, making them ideal for handling hazardous or high-purity fluids in chemical and pharmaceutical industries.

Low Maintenance Requirements – The self-lubricating properties of PTFE reduce wear and friction, minimising operational downtime and lowering maintenance costs.

Versatile Application – PTFE sleeved plug valves provide on/off and throttling capabilities, making them suitable for a wide range of flow control applications.

Reliable Performance in Harsh Conditions – Their robust design allows them to function effectively in high-temperature, high-pressure, and abrasive environments.

The increasing adoption of PTFE sleeved plug valves highlights their critical role in improving flow control efficiency, reducing maintenance, and enhancing system reliability across multiple industries in the UK and beyond.

Quality Assurance: Our Commitment to Excellence

We take pride in our stringent quality control processes, ensuring that every valve that leaves our facility meets the highest standards. Just today, our team completed a thorough quality check on another batch of Alloy 20 PTFE sleeved plug valves, ready to be packed and shipped to our valued customers. This commitment to quality is the cornerstone of our success and a testament to our dedication to customer satisfaction.

PTFE Sleeved Plug Valves: The Ideal Solution for Demanding Applications

PTFE sleeved plug valves are renowned for their exceptional chemical resistance, low friction, and superior sealing capabilities. These attributes make them the perfect choice for a wide range of applications, including:

- Chemical processing: Where corrosive media and high temperatures are common.

- Pharmaceutical manufacturing: Where hygiene and purity are paramount.

- Food and beverage production: Where contamination must be avoided.

- Oil and gas exploration: Where harsh environments and extreme pressures are present.

KDV: Your Trusted Partner for Industrial Valves

With our extensive experience in lined valve manufacturing and our dedication to quality, KDV is your trusted partner for all your industrial valve needs. We offer a wide range of PTFE sleeved plug valves, including Alloy 20 options, to meet the specific requirements of your application.

Frequently Asked Questions (FAQ) – PTFE Sleeved Plug Valves

1. How do PTFE sleeved plug valves compare to other isolation valves in terms of sealing and durability?

PTFE sleeved plug valves provide bubble-tight sealing, ensuring zero-leakage performance, which is critical in handling hazardous, high-purity, or corrosive fluids. Unlike ball valves, which may require frequent seal replacements, PTFE-lined plug valves have a self-lubricating sleeve that reduces wear and friction, leading to longer service life and minimal maintenance. Their robust design also prevents fluid entrapment, making them superior in applications where contamination or buildup is a concern.

2. What is the maximum pressure and temperature rating for PTFE sleeved plug valves?

The operating limits of PTFE sleeved plug valves depend on the material composition and specific manufacturer design. Generally, they can withstand pressures up to 40 bar (600 psi) and temperatures ranging from -20°C to 200°C. For high-pressure or extreme temperature environments, it’s essential to verify compatibility with your system requirements and consult with the manufacturer to select the appropriate valve specification.

3. Are PTFE sleeved plug valves suitable for highly corrosive and abrasive applications?

Yes, PTFE sleeved plug valves are highly resistant to aggressive chemicals, acids, and alkalis, making them ideal for chemical processing, wastewater treatment, and pharmaceutical applications. The PTFE sleeve acts as a corrosion barrier, preventing the valve body from direct contact with process fluids. However, for abrasive media, it’s crucial to confirm that the valve design can handle solid particles or slurries without excessive wear.

4. What factors should be considered when selecting a PTFE sleeved plug valve for my application?

When choosing a PTFE sleeved plug valve, consider the following:

Fluid Compatibility – Ensure the PTFE lining is suitable for the chemicals or fluids being processed.

Pressure & Temperature Ratings – Verify that the valve can withstand your system’s operating conditions.

End Connections – Choose between flanged, threaded, or welded options based on your piping system.

Flow Control Needs – Determine if your application requires full-bore flow, throttling capability, or standard shut-off.

Maintenance Accessibility – Consider ease of servicing, as some applications require frequent cleaning or inspection.

5. How do PTFE sleeved plug valves contribute to reduced maintenance costs and system reliability?

PTFE sleeved plug valves are self-lubricating, meaning they require minimal greasing or seal replacements, reducing long-term maintenance costs. Their smooth, non-stick lining prevents buildup of scale, debris, or chemical residues, ensuring longer service life and consistent valve performance. Additionally, their tight shut-off capabilities prevent leakage, reducing product loss and improving system efficiency. For industries focused on reducing downtime and optimising plant operations, these valves provide a cost-effective and reliable solution.

If you’re looking for reliable, high-performance plug valves in the UK, look no further than KDV. Contact us today to learn more about our products and services.