5 important facts from industries that use Weir Type Diaphragm Valve

Weir type diaphragm valves are widely used in many industries for their excellent performance and reliability when controlling the flow of fluids. Here are 5 important facts about weir type diaphragm valves that you may not know:

- A Legacy from Ancient Rome

The first recorded use of a diaphragm type valve dates back to ancient Rome, where rudimentary designs were employed to regulate water flow and temperature in the famous Roman hot baths. These early versions showcased a remarkable understanding of fluid dynamics, highlighting the ingenuity of ancient engineering that laid the groundwork for modern diaphragm valves.

- Unparalleled Versatility Across Applications

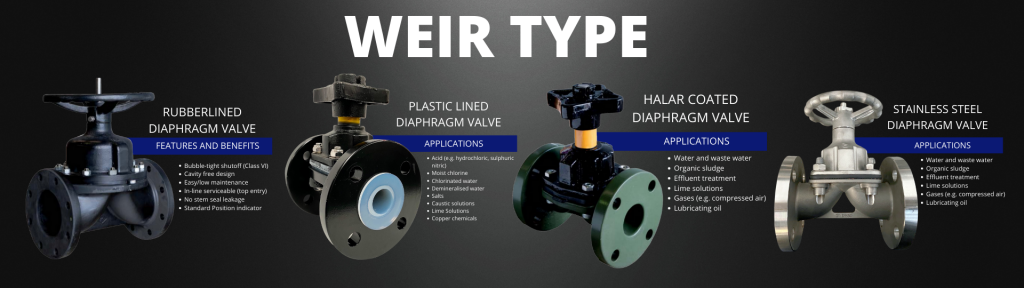

Today they are one of the most versatile types of valves available, Their design allows them to perform various functions, including precise process control, flow regulation, and even pressure relief. Industries such as chemical processing, water treatment, and biopharmaceutical manufacturing rely on these valves due to their compatibility with a wide range of fluids, including corrosive and abrasive substances.

- A Design That Excels in Safety

Unlike other types of valves, weir type diaphragm valves are hermetically sealed which means it eliminates the risk of leaks, making them a top choice for hazardous or explosive environments. Their seal protects against contamination, ensuring safety in critical applications like handling toxic chemicals or sterile pharmaceutical processes.

- Cavity-Free Construction for Hygienic Applications

Unlike other valves by nature of design the Weir type diaphragm valve is cavity free, making them ideal for applications requiring high levels of cleanliness. These valves are staples in industries like food and beverage production, clean water systems, and pharmaceuticals, where sanitary operation is paramount.

5.A Valve with Many Names

Weir type valves have multiple nick names – some of which are saddle valve, block Valves, A type valves and ridge valves, occasionally mistakenly called a pinch valve,However, the two are distinct; pinch valves use a pinching mechanism to control flow, while diaphragm valves rely on a flexible membrane that compresses against the weir to regulate or stop flow.

Applications of Weir Type Diaphragm Valves

In the mining industry, weir type valves are used to control chemical dosing applications, water treatment and control of process gases.

Scenario: In copper mining, companies like Rio Tinto utilize these valves in flotation processes where precise chemical dosing is required to separate ore from impurities

In the Oil and gas industry weir type valves are used in a variety of applications, such as desalination, Demin water and fire suppression

Scenario: Offshore drilling platforms operated by companies like Shell incorporate weir type valves in fire suppression systems, ensuring the safe handling of water and fire-retardant chemicals under high-pressure conditions.

In the food and beverage industry, weir type valves are commonly used in milk processing plants as they can maintain a constant flow rate and prevent contamination.

Scenario: In dairy facilities like those operated by Nestlé, weir type valves ensure hygienic control of milk flow during pasteurization and homogenization processes.

In the pharmaceutical industry weir type valves are used in the manufacturing process purified water, and the flow control of certain liquid and powdered chemicals. The weir type valve is able to control the flow of materials with great accuracy which is essential in tablet making.

Scenario: Companies like Pfizer rely on these valves in tablet-making lines to regulate the flow of granulation fluids and ensure consistent quality in medication.

FAQs About Weir Type Diaphragm Valves

- What materials are commonly used for the diaphragms in weir type valves, and how do they affect performance in different industries?

Understanding how materials like EPDM, PTFE, or natural rubber influence valve compatibility with chemicals, temperatures, and sterilization processes is essential.

- How do weir type diaphragm valves compare to ball valves or gate valves in terms of maintenance and operational longevity?

This question addresses practical concerns about downtime, ease of servicing, and cost-efficiency across various applications.

- What are the key considerations for selecting a weir type diaphragm valve for corrosive or abrasive fluid applications?

Factors such as body material (e.g., stainless steel or PVC) and diaphragm resilience are critical for ensuring reliability in demanding environments.

- How do weir type valves ensure contamination-free operation in pharmaceutical and food manufacturing?

Features like cavity-free design, hermetic sealing, and compliance with industry standards (e.g., FDA, USP Class VI) make them ideal for hygienic applications.

- Can weir type diaphragm valves handle high-pressure applications, and what are their pressure and temperature limitations?

Details about pressure ratings and operational temperatures help determine their suitability for processes like fire suppression or desalination.

Get Diaphragm Valves Information

Weir type diaphragm valves are a versatile type of valve that is used in many industries for a variety of purposes. Recently, we had a customer in urgent need of 10 off DN100 ETFE lined weir type diaphragm valves, heading to South Yorkshire on to a steel mill for their pickling plant. The weir type diaphragm valves will be used to control the flow of hydrochloric acid.

At KDV we place great importance on the quality lead times and quick responses for our customers. 10 units were assembled, tested and ready for dispatch in under two working weeks, 1 week earlier than suggested. We always want to have the orders ready ahead of schedule.

Have an enquiry? Contact us at info@kdvflow.co.uk or give us a call at +44 1924 846909