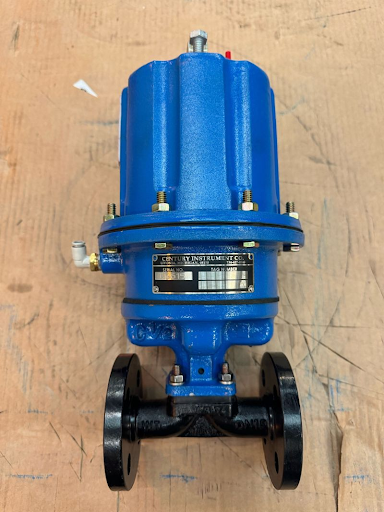

Diaphragm Valves with Pneumatic Actuation: A KDV Flow Specialty

The past few weeks have been a whirlwind of activity for our automation team at KDV Flow, as they’ve been busy assembling a wide range of pneumatic linear actuation packages. While we specialize in a variety of sizes and configurations, there’s something particularly satisfying about completing a run of larger actuators with a compact and elegant DN15 Series 1 (DIN) Weir type diaphragm valve.

Why Choose Diaphragm Valves with Pneumatic Actuation?

Diaphragm valves are known for their exceptional reliability, leak-tightness, and ability to handle corrosive or abrasive media. When combined with pneumatic actuation, they offer a powerful and versatile solution for a wide range of industrial applications, including:

- Chemical Processing: Diaphragm valves with pneumatic actuation excel in chemical processing applications due to their excellent corrosion resistance and ability to handle harsh chemicals. The leak-tight closure and smooth flow path minimize contamination risks and ensure precise control over fluid flow.

- Food and Beverage Production: In the food and beverage industry, hygiene and sanitation are paramount. Diaphragm valves with pneumatic actuation meet these requirements with their cleanable design and ability to handle food-grade materials without compromising purity.

- Pharmaceutical Manufacturing: Similar to food and beverage production, diaphragm valves with pneumatic actuation are ideal for pharmaceutical applications due to their sterility and ability to handle sensitive materials. The precise control offered by pneumatic actuation ensures consistent and reliable operation in critical processes.

- Water and Wastewater Treatment: Diaphragm valves with pneumatic actuation are well-suited for water and wastewater treatment applications due to their durability, corrosion resistance, and ability to handle slurries and abrasive media. The tight shut-off capability minimizes leaks and prevents contamination of clean water supplies.

Key Benefits of Pneumatic Actuation for Diaphragm Valves

Pneumatic diaphragm valves offer several advantages over manually operated or electrically actuated valves. Here’s a closer look at some of the key benefits:

- Precise control: Pneumatic actuators provide accurate and responsive control over valve position, allowing for precise flow regulation.

- Reliability: Pneumatic systems are known for their durability and low maintenance requirements, ensuring long-lasting performance.

- Safety: Pneumatic actuators are inherently safe, as they do not pose an electrical hazard and can operate in hazardous environments.

- Versatility: Pneumatic actuators can be easily integrated with a variety of control systems, making them adaptable to different automation needs.

Weir Type Diaphragm Valves: The KDV Flow Advantage

Our Weir type diaphragm valves are designed to provide optimal flow control and isolation, even in demanding applications. The weir design minimizes turbulence and pressure drop, ensuring smooth and efficient operation. Combined with our high-quality lined valve manufacturing, these valves offer exceptional resistance to corrosion and abrasion.

KDV Flow: Your Partner for Automated Valve Solutions

At KDV Flow, we’re committed to providing our customers with the highest quality diaphragm valves and actuation solutions. Our experienced team can help you select the right valve and actuator combination for your specific needs, ensuring optimal performance and reliability.

If you’re looking for reliable, efficient, and versatile diaphragm valves with pneumatic actuation in the UK, contact KDV Flow today. We’ll be happy to discuss your requirements and provide you with a customized solution.